Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

** Title: Saltwater’s Worst Headache: Armoring Titanium-Steel Pumps and Valves Versus Rust **.

(Long-Term Corrosion Protection Solutions For Titanium-Steel Composite Plates For Seawater Pumps And Valves)

Deep sea pumps and valves encounter a brutal adversary every day: rust. It’s a quiet awesome. Left untreated, rust eats away at steel, deteriorates structures, and creates pricey failures. No one desires their critical salt water systems falling short unexpectedly. That downtime costs serious money.

So, just how do you combat this relentless enemy, particularly in the super-aggressive deep sea atmosphere? Regular steel alone just will not suffice for the long haul. It requires serious backup. Go into titanium-steel composite plates. This combination packs an effective punch versus deterioration.

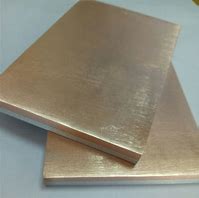

Think of these composite plates like a superhero team-up. You get the amazing toughness and price of steel. Steel forms the solid foundation. After that you add titanium. Titanium is normally difficult. It forms an extremely thin, super-stable oxide layer when revealed to air or water. This layer acts like a virtually impenetrable shield. It laughs at salt spray, chlorine, and various other unpleasant stuff in salt water. The titanium layer ends up being the frontline defense.

Yet just sticking titanium onto steel isn’t magic. You need clever engineering. The genuine secret sauce is how you bond these two steels together securely. This bond is important. It must be perfect. Any kind of vulnerable point, any tiny void, is an open invitation for corrosion to sneak in beneath. Water discovers a means. It constantly does. Poor bonding indicates the titanium shield stops working. The steel below obtains struck.

That’s where the long-lasting security remedies can be found in. It’s not just about the materials. It has to do with the procedure. Experts make use of advanced techniques like surge welding or hot rolling under extreme stress. These methods create a metallurgical bond. The metals fuse with each other at the atomic degree. The result is a smooth, extremely strong link. No spaces. No powerlessness. Saltwater just can not permeate this bond.

The titanium layer does the hefty training. It compromises nothing. It simply rests there, passively shielding the steel core. This easy protection is key. It indicates the protection system functions regularly without needing electrical power or chemicals. It’s maintenance-free shield.

The advantages for salt water pumps and valves are massive. First, you obtain considerably much longer life expectancies. These components ins 2015 much longer than typical steel components. Second, reliability skyrockets. Unanticipated failings become rare. Operators gain satisfaction. Third, upkeep prices drop. You aren’t continuously changing rusted-out components. The upfront expense is greater. The long-lasting financial savings are enormous.

Choosing the right composite plate supplier matters. Seek proven knowledge in bonding titanium to steel particularly for marine use. Inquire about their quality assurance. They need to guarantee the honesty of that important bond. It’s the foundation of everything. Check their record with real seawater applications.

(Long-Term Corrosion Protection Solutions For Titanium-Steel Composite Plates For Seawater Pumps And Valves)

Pumps moving salt water and valves regulating its circulation face constant attack. Using titanium-steel composite plates isn’t just an upgrade. It’s crucial shield. It transforms susceptible parts right into durable, durable properties. This technology stops deep sea deterioration dead in its tracks. It maintains vital systems running smoothly, dependably, and cost-effectively for the long run.