Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

PRODUCT PARAMETERS

Description

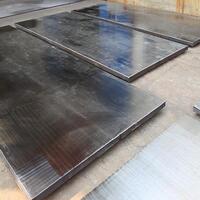

Overview of Carbon Steel Plate

Carbon steel plates are fundamental materials used across various industries due to their strength, versatility, and cost-effectiveness. They are composed primarily of iron and carbon, with small amounts of other elements. These plates can be cut, formed, and joined in numerous ways to suit different applications, ranging from construction to manufacturing.

Features of Carbon Steel Plate

High Strength: Offers excellent mechanical properties for demanding applications.

Versatility: Suitable for a wide range of industrial uses including structural, machinery, and tooling.

Cost-Effective: Provides an economical solution without compromising on performance.

Ductility: Can be easily shaped or formed into desired configurations.

Durability: Resistant to wear and tear, ensuring long-lasting performance.

Weldability: Capable of being welded without loss of integrity or strength.

(Hot Rolled Ship Building 6mm 8mm 9mm 12mm Thickness Black Surface Carbon Steel Sheet Plate)

Specifications of Hot Rolled Ship Building 6mm 8mm 9mm 12mm Thickness Black Surface Carbon Steel Sheet Plate

These steel plates come in several thicknesses. We offer 6mm, 8mm, 9mm, and 12mm options. These are common sizes for shipbuilding. The surface is black. This black finish is mill scale. Mill scale forms during hot rolling. It’s a natural oxide layer. It protects the steel slightly. This steel is carbon steel. Carbon steel is strong. It handles heavy loads well. It’s durable for harsh marine environments. Ships need reliable materials. These plates provide structural strength.

The material grade is usually A or AH grade. This meets shipbuilding standards. Standards like ASTM A131 are typical. These plates are hot rolled. Hot rolling makes them tough. It improves their mechanical properties. Thickness tolerance is important. Tolerances follow industry norms. Widths range from 1500mm to 3000mm. Common widths are 1800mm, 2000mm, 2200mm, and 2500mm. Lengths are usually 6000mm, 8000mm, 9000mm, or 12000mm. Custom sizes are possible.

Each thickness serves specific purposes. Thinner plates, like 6mm, suit lighter structures. These might be internal bulkheads. Slightly thicker plates, 8mm and 9mm, are versatile. They work for decking and hull sections. The 12mm plate is heavier. It’s used for critical load-bearing parts. Think bottom hull plates. All thicknesses weld well. Good weldability is crucial for ship assembly. They also handle forming operations acceptably.

These steel plates resist corrosion reasonably. Mill scale offers some protection. Proper surface prep is needed before painting. Ships require extensive painting systems. These plates form the core structure. They ensure the vessel’s integrity. Strength and reliability are non-negotiable. This steel meets those demands. It’s a fundamental material for marine construction.

(Hot Rolled Ship Building 6mm 8mm 9mm 12mm Thickness Black Surface Carbon Steel Sheet Plate)

Applications of Hot Rolled Ship Building 6mm 8mm 9mm 12mm Thickness Black Surface Carbon Steel Sheet Plate

Hot rolled ship building steel plate comes in common thicknesses like 6mm, 8mm, 9mm, and 12mm. Builders use this steel for constructing large ocean vessels. It is carbon steel with a natural black surface finish. This finish comes from the hot rolling process itself. The steel is heated and rolled into plates. It cools naturally in air. This method gives the steel its black color and scale layer.

This steel offers high strength and toughness. Ships face harsh conditions at sea. They need strong materials. Hot rolled plates provide that strength. They handle stress well. The material also bends and shapes easily. Ship hulls and decks have complex curves. Builders form these plates without too much trouble. The steel’s good weldability is another key point. Connecting plates is vital in shipbuilding. Welders join sections reliably with this steel.

The black surface is not just untreated. It offers some protection. The mill scale layer acts as a barrier. It helps resist corrosion initially. This is useful before final coatings are applied. Shipyards often apply protective paints later. The steel’s affordability matters too. Building a ship requires tons of material. Shipyards need cost-effective options. Hot rolled plate delivers good performance for the price.

Company Introduction

Welcome to Wgraj, a premier global supplier of high-quality metal cladding solutions. We specialize in providing a wide range of metal cladding products, including aluminum, steel, and copper composites, designed to meet the diverse needs of architects, builders, and designers. Our commitment to innovation, durability, and aesthetic excellence ensures that our clients receive top-tier materials for their projects. With state-of-the-art manufacturing facilities and a dedication to customer satisfaction, we deliver reliable, cost-effective solutions worldwide. Partner with us for your metal cladding needs and experience unmatched quality and service.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Hot Rolled Ship Building 6mm 8mm 9mm 12mm Thickness Black Surface Carbon Steel Sheet Plate

Here are 5 common questions about our Hot Rolled Ship Building Steel Plates in thicknesses like 6mm, 8mm, 9mm, and 12mm.

What is this ship building steel plate?

This is carbon steel plate made for ship construction. It comes hot rolled. This means the steel is heated very hot then shaped into plates. The surface is black. Thicknesses like 6mm, 8mm, 9mm, and 12mm are popular sizes. These plates are tough. They handle marine environments well.

Why use hot rolled steel for ships?

Hot rolling makes the steel strong. It improves the steel’s structure. Ships need strong plates. They face salt water, waves, and heavy loads. Hot rolled plates are reliable for hulls, decks, and other structural parts. They weld well too. Good welding is crucial for shipbuilding.

What about the black surface?

The black surface comes from the hot rolling process. It’s a natural oxide layer. This layer forms when the hot steel cools in air. It protects the steel a bit. But this surface is not a final finish. It will need cleaning before painting or coating. The black surface is typical for hot rolled steel.

How strong are these plates?

These plates are very strong. They meet specific shipbuilding standards. They are designed to be impact resistant. They have good toughness. This toughness is vital for ships. Ships experience stress. The steel must not crack easily. These plates handle high loads safely.

Where are these thicknesses used on a ship?

Different thicknesses suit different parts. Thinner plates like 6mm and 8mm often go into bulkheads or lighter structures. Plates like 9mm and 12mm are thicker. They are used for the main hull, the keel, or areas needing extra strength. The exact use depends on the ship design and the required strength.

(Hot Rolled Ship Building 6mm 8mm 9mm 12mm Thickness Black Surface Carbon Steel Sheet Plate)

REQUEST A QUOTE

RELATED PRODUCTS

Whole Q235 Hot Rolled Steel Low Carbon Steel Plate 6 Mm Thick 1.5 M Wide Steel Plate

High Quality carbon Structural steel Sheet 1065 High carbon steel plate

China Hot Rolled Steel Plates Q235 Black Steel Sheet Low Carbon Steel Sheet for Building

Plate/Sheet High Quality S355 Carbon Steel Alloy Steel Structural Metal Bis Certified ASTM A36 Steel Plate

Ms Hot Rolled S45c 5mm 15mm 20mm 50mm Mold Steel Plate Used Carbon Steel Free Cutting Steel Plate Q245r Gb/t713 14 Days