Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

** Spark Secrets: Just How Copper-Steel Duo Powers High-Voltage Equipment **.

(Analysis Of The Conductivity Of Copper-Steel Composite Plates In High-Voltage Switchgear)

Ever wonder what maintains your lights on throughout a beast tornado? Or how huge factories hum without blowing a fuse? A huge component of the solution conceals inside simple metal boxes: high-voltage switchgear. These are the silent guardians controlling large electrical circulations. Today, we peek inside one crucial piece– the copper-steel composite plate. This isn’t nearly steel; it’s about clever teamwork under pressure.

Consider electrical power like hurrying water. It requires a smooth, wide path. Copper is the super star here. It lets electrons zoom through with marginal resistance. That’s vital. Less resistance implies less squandered energy. Much less thrown away energy implies much less heat. Warm is the enemy in electrical systems.

However copper has a weak point. It’s fairly soft. Inside high-voltage switchgear, things obtain intense. Massive currents rise. Strong mechanical pressures act throughout changing. Copper alone might flex or warp in time. That spells difficulty. A bent call factor can cause arcing, overheating, also failure. We require strength.

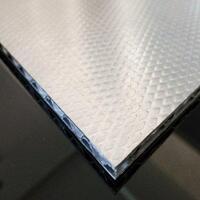

Go into steel. Steel is tough. It laughs at mechanical tension. It supplies the muscle, the backbone, that copper does not have. Putting them together creates a superhero product: the copper-steel composite plate. Copper deals with the electric hefty training on the surface. Steel below gives strong assistance, keeping whatever stiff and in place.

This combo resolves huge problems. Initially, conductivity remains high since copper faces the present. Second, the steel core makes sure home plate does not deform. Contacts remain flawlessly straightened. Good call is every little thing. Poor get in touch with produces resistance spots. Resistance areas develop extreme warmth. Intense warmth can thaw points. No one wants that.

The magic remains in the bond. These plates aren’t just stuck together. They’re commonly explosively bonded or exactly bonded under high pressure. This develops a near-seamless join. Electricity flows quickly across the copper face. The steel core stays a stable, stubborn foundation. It’s a perfect partnership.

Why not utilize solid copper? Expense and practicality. Solid copper thick adequate to be solid would be extremely costly. Copper is expensive. The composite usages just enough copper where it matters most– the call surface area. Steel, being less expensive and stronger, creates the mass. This saves money without sacrificing efficiency.

(Analysis Of The Conductivity Of Copper-Steel Composite Plates In High-Voltage Switchgear)

Next time you turn a switch, keep in mind the hidden heroes. Inside substations and nuclear power plant, these copper-steel plates are working hard. They handle the raw power securely. They guarantee reliable links. They handle the warmth and the force. They are a dazzling example of design smarts. Two different steels, one best remedy for maintaining our high-voltage globe running efficiently.