Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

Titanium Armor: Why Chemical Pipelines Demand Challenging Skins

(Compression And Corrosion Resistance Of Titanium-Steel Composite Plates For Chemical Pipelines)

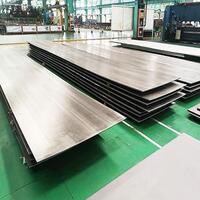

Chemical pipelines face a brutal world. Believe acids solid enough to liquify steel. Think extreme pressure pushing from the within. Think continuous temperature swings. Regular steel pipelines? They commonly shed this battle. They corrosion, they weaken, they fail. This sets you back money. Worse, it takes the chance of hazardous leaks. So what’s the response? Forget magic. Believe brilliant design. Assume titanium-steel composite plates.

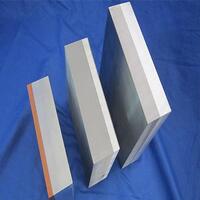

Visualize this. You take extremely solid steel. Steel is great under pressure. It handles heavy lots well. Now, coat its inner surface area dealing with all those awful chemicals with titanium. Titanium is naturally challenging. It laughs at a lot of acids and salts. It doesn’t rust conveniently. This combination is a powerhouse. It resembles giving the pipe a super-tough inner skin.

The compression part is crucial. Pipes aren’t simply resting there. Liquids pump through them under high pressure. The pipeline walls obtain squeezed. They need to stand up to squashing or buckling. Steel offers this backbone. It’s the muscle mass holding everything with each other. The titanium layer, adhered tightly to the steel, includes some stamina also. However its main task is defense versus chemical assault.

The corrosion resistance is the real celebrity, though. Inside a chemical pipeline, it’s a battle zone. Hostile stuff like sulfuric acid, hydrochloric acid, or salty brines constantly assault the pipeline wall. Steel alone rusts quick. Titanium? It creates an exceptionally thin, super-stable oxide layer on its surface promptly. This layer is like an undetectable shield. It quits the chemicals from consuming into the steel beneath. This guard even fixings itself if scratched. So the pipe remains undamaged, leak-free, for years longer.

Making these composite plates isn’t easy. You can not simply glue titanium onto steel. The bond needs to be ideal. Definitely solid. No voids. No weak spots. Methods like explosive welding or warm rolling fuse the metals together at a molecular level. This produces a solitary, unified plate. The bond is so solid it will not peel apart under stress and anxiety or warm. This best bond is vital. It indicates the challenging titanium skin functions effortlessly with the strong steel core.

The benefits are big. Pipes built with this titanium-steel armor last much, much longer. They stand up to leakages much better. They require far less upkeep. They deal with the toughest chemicals securely. This saves companies huge amounts of money over time. No consistent pipe substitutes. Less downtime for repair work. Safer procedures for employees and the setting.

(Compression And Corrosion Resistance Of Titanium-Steel Composite Plates For Chemical Pipelines)

It’s a wise service born from understanding the issue. Chemical pipelines need brute strength inside and out. They need an impervious shield against chemical warfare. Integrating steel and titanium gives them both. It’s not simply a pipe. It’s a pipeline built to endure. Developed to shield. Developed for the long run. That’s the power of a well-engineered skin.