Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

Forget boring metal sandwiches. Copper-steel plates are secretly making your next electric car motor way better. Seriously, these clever composites are the unsung heroes powering the future of electric vehicles.

(Copper-Steel Composite Plates Provide Efficient Conductive Materials For New Energy Vehicle Motors)

Think about your car’s motor. It needs to spin powerfully and efficiently. This takes massive amounts of electricity flowing smoothly. Heat is the enemy here. Too much heat slows things down, wastes energy, and can even break things. Old-school motors often used just copper or just steel parts. Copper is amazing for carrying electricity. Steel is super strong and handles heat well. But alone, each has problems. Pure copper gets too soft when hot. Pure steel just isn’t a great electricity conductor.

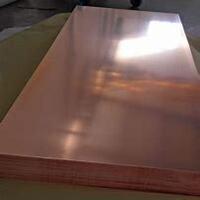

So engineers got smart. They thought, “Why not stick them together?” Copper-steel composite plates are exactly that. Imagine a thin, strong layer of steel firmly bonded to a layer of highly conductive copper. It’s like a perfect team. The copper layer becomes the express lane for electrical current. It lets the juice flow fast with minimal resistance. Less resistance means less wasted energy turning into heat. That’s good news for your car’s range.

Meanwhile, the steel layer is the tough guy. It provides serious mechanical strength. It stops the whole assembly from warping or sagging under the intense heat and magnetic forces inside the motor. Steel also acts like a heat sink. It pulls heat away from the hot copper, spreading it out and helping the motor stay cooler overall. Cooler motors run more efficiently and last much longer.

This teamwork solves big headaches. Before, motor designers often needed complex cooling systems or bulky structures to manage heat and strength. Copper-steel plates simplify things. They let electricity flow freely where it’s needed most, right near the motor’s core. They also handle the physical stress without breaking a sweat. This means motors can be smaller, lighter, and pack more punch. Smaller, lighter motors mean lighter cars. Lighter cars go farther on a single charge.

Manufacturing these plates is clever too. Special processes bond the copper and steel layers incredibly tightly. Think intense pressure and high heat. This creates a single, unified material. The bond is so strong, electricity and heat move easily across the join. There’s no weak spot. This reliability is crucial for car makers building millions of vehicles.

(Copper-Steel Composite Plates Provide Efficient Conductive Materials For New Energy Vehicle Motors)

The result? Motors that are simply better. They waste less energy as heat. They deliver more power reliably. They can be designed smaller and lighter. All this translates directly to the electric cars you see on the road: longer driving range, quicker acceleration, and potentially lower costs. Next time you see a sleek new EV zoom past quietly, remember the tiny, powerful motor inside. Chances are, copper and steel are working together perfectly, thanks to this smart composite plate technology. It’s a small material making a huge difference.