Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

Visualize a refinery. Flames holler. Temperatures rise past anything you would certainly locate in a cooking area stove. Steel components inside face an unnoticeable enemy every day. This opponent isn’t unexpected impact. It’s slow, ruthless contortion. We call it “creep.” Under extreme warmth and consistent pressure, even strong steels progressively extend. They sag. They shed their form over months or years. This is a huge migraine for refinery drivers. Devices fails. Manufacturing quits. Prices increase.

(Nickel-Based Alloy Composite Plates Improve High-Temperature Creep Resistance Of Refining Equipment)

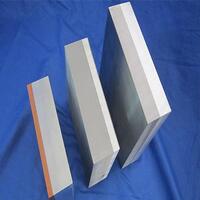

Go into the hero: nickel-based alloy composite plates. Think about them as sophisticated shield for important refinery parts. These aren’t your typical steel plates. They are unique. They are constructed for the snake pit.

The issue with traditional products is straightforward. High warmth makes atoms move around a lot more conveniently. Constant stress presses those atoms misplaced. Over time, the steel structure weakens. It slowly streams, like chilly tar. This creep brings about cracks. It causes leakages. It brings about tragic failures. Refineries need tools that lasts. They require parts that will not gradually surrender to the warmth.

Nickel alloys are various. They have a trump card: their atomic structure. Nickel atoms bond securely with other aspects like chromium and molybdenum. This creates a super-stable lattice. It resembles developing a fortress at the tiny level. Heat energy has a hard time to make these atoms move. Stress locates it much harder to push them around.

Composite plates take this further. They frequently layer this hard nickel alloy onto a strong base steel. This integrates the most effective features. You get the extraordinary creep resistance of the nickel alloy externally. That’s where the heat and stress and anxiety struck hardest. Below, you obtain the architectural toughness and cost-effectiveness of steel or one more alloy. It’s teamwork at the material degree.

The result? Equipment lasts considerably longer in the harsh refinery setting. Think of vital elements like reactor liners. Consider piping sections revealed to extreme heat. Consider catalyst support grids. These plates imitate a shield versus creep contortion. They maintain their form. They keep their strength. They protect against the slow, inevitable drooping that afflicts lesser products.

This suggests less unexpected downtime. Less emergency repairs. Lower maintenance expenses over the tools’s lifetime. More constant manufacturing result. Operators gain peace of mind. Their equipment isn’t slowly disappearing within. It stays solid. It remains trustworthy. It deals with the warmth every day, year after year.

(Nickel-Based Alloy Composite Plates Improve High-Temperature Creep Resistance Of Refining Equipment)

Utilizing these advanced plates is a smart investment. It directly takes on a major failing setting in high-temperature refining. The steel doesn’t burn out. It doesn’t slowly quit. It just maintains functioning under stress. That’s the power of nickel alloy shield in the heart of the fire.