Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

** Title: Nickel Alloy Shield: The Secret to Longer-Lasting Petrochemical Tools **.

(Nickel-Based Alloy Composite Plates Improve The Service Life Of Petrochemical Equipment)

Visualize a petrochemical plant. Makers roar. Pipelines turn like steel serpents. Temperature levels soar. Destructive chemicals hiss via every shutoff and container. This is a field of battle, and the devices here faces a day-to-day battle against wear, heat, and decay. But there’s a hero in this story: nickel-based alloy composite plates. These plain steel layers are quietly revolutionizing for how long petrochemical equipment makes it through in the toughest conditions.

Let’s simplify. Petrochemical devices deals with unpleasant stuff– acidic substances, severe heat, relentless stress. In time, these variables eat with average metals. Cracks form. Leakages take place. Closures for repair services set you back money and time. However nickel-based alloys? They’re like armor. Think of them as a guard bonded onto crucial parts of activators, pipes, or tank. The base layer may be challenging steel, yet the nickel alloy finish? That’s the real star. It pokes fun at corrosion. It brushes off blistering temperatures.

Why does this matter? Initially, cash. Replacing damaged tools is expensive. Unexpected closures? Even worse. Nickel alloy composites let makers ins 2014 longer. One chemical plant in Texas covered their reactor interiors with these plates. Result? They pushed maintenance intervals from 6 months to over 3 years. That’s less downtime, even more performance.

Second, security. Weak points in equipment can result in disasters– leakages, explosions, ecological harm. Nickel alloys reduce these risks. They’re stubbornly resistant to fractures. Even when the base metal begins to exhaustion, the nickel layer holds solid. It resembles having a backup protector.

But how do these alloys function? It’s everything about chemistry. Nickel naturally partner with elements like chromium and molybdenum. Together, they develop a microscopic obstacle. This barrier obstructs corrosive chemicals from consuming into the steel. Heat resistance? Nickel’s melting point is overpriced– over 2,500 ° F. So when temperatures increase, the alloy remains strong. No warping. No weakening.

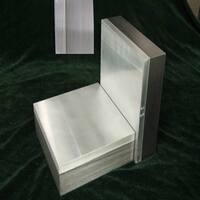

Here’s the amazing part: these plates aren’t simply put onto equipment. They’re integrated utilizing innovative strategies like explosion welding or warm rolling. The bond in between the nickel layer and the base steel isn’t simply strong– it’s smooth. No spaces for rust to slip into. No weak joints.

Take valves, for example. Shutoffs manage the flow of hostile chemicals. When their surfaces are coated with nickel alloy, they stand up to years of misuse. Very same with pipelines. Underground pipes face wetness, dirt acids, and pressure. Nickel-armored pipelines? They last longer than conventional ones by decades.

Some could claim, “But nickel alloys set you back a lot more upfront!” True. Yet the math prefers long-lasting gains. A pump made with carbon steel could last 2 years in a destructive setting. Swap in a nickel-clad version? That pump can offer for 15 years. Over time, the savings accumulate. Less substitute. Fewer repairs. Even more uptime.

The petrochemical industry is catching on. Refineries, chemical processors, also overseas rigs are embracing these compounds. It’s not a flashy pattern– it’s a useful shift. Engineers call it a “game-changer.” Operators sleep less complicated recognizing their gear will not fall short mid-shift.

(Nickel-Based Alloy Composite Plates Improve The Service Life Of Petrochemical Equipment)

So following time you see a petrochemical plant, remember: concealed below the grit and noise, nickel alloy armor goes to job. It doesn’t shine. It does not flaunt. However it’s the factor those equipments maintain humming time after time, fighting the components– and winning.