Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

** Stainless Steel Composites Under Stress: Testing Toughness in Vessel Manufacturing **.

(Safety Assessment Of Stainless Steel Composite Plates In Pressure Vessel Manufacturing)

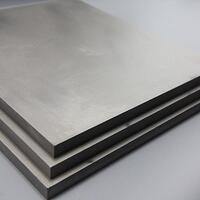

Stress vessels are the unrecognized heroes of industries like oil, gas, and chemicals. They hold hazardous stuff under severe conditions. Making them solid and risk-free is a large offer. One material getting interest these days is stainless steel composite plates. They mix durability with price financial savings. Let’s break down exactly how these products are tested for security and why they matter.

Stainless steel composites are like a sandwich. The top layer is stainless-steel. It resists rust and deals with harsh chemicals. The bottom layer is carbon steel. It’s less expensive however still difficult. Glued with each other, they produce a product that’s both durable and economical. Yet exactly how do designers recognize these plates won’t fall short under pressure? Examining beginnings long before they’re bonded right into a vessel.

Initially, labs examine the bonding between both steel layers. Weak points below could break under anxiety. Engineers make use of equipments to draw, flex, and spin samples. They want to see how much force the compound can take in the past splitting. If the bond holds, it’s a win. If not, back to the attracting board.

Successive: non-destructive testing. This phase resembles a medical checkup for metal. Service technicians make use of ultrasound waves to search for surprise defects. Acoustic waves get better in different ways if there’s a crack or air pocket. X-rays are an additional device. They show the internal framework without reducing the steel open. These tests area issues early, conserving money and time.

Real-world simulations follow. Pressure vessels face warm, cold, and constant pressure changes. Examination chambers recreate these extremes. Compound plates are heated until they glow, then cooled down quickly. They’re pressurized beyond regular limitations. Engineers look for warping, leakages, or unexpected breaks. The objective is to find the breaking point– and remain far listed below it in actual usage.

Welding is a huge obstacle. Signing up with composites to other components can damage the bond. Too much warmth ruins the stainless layer’s anti-rust powers. Skilled welders use special methods. They maintain temperature levels specific and add filler metals to shield the joint. After welding, more tests ensure the joints stand up.

Why undergo all this difficulty? Standard strong stainless steel vessels work fine, however they’re costly. Compounds cut expenses without skimping on safety. They’re lighter also, that makes delivery and setting up easier. For sectors watching budgets, this balance is gold.

Area efficiency is the final test. Compound plates in energetic vessels face everyday whippings– chemicals, stress spikes, temperature swings. Engineers track these vessels over years. They seek rust, fatigue, or unanticipated failings. Thus far, outcomes are promising. Numerous compounds outlast older materials, proving the examinations function.

(Safety Assessment Of Stainless Steel Composite Plates In Pressure Vessel Manufacturing)

Safety isn’t nearly passing exams. It’s about trusting a material to shield lives and equipment. Stainless-steel compounds are making that depend on. With extensive checks and clever layout, they’re reshaping just how pressure vessels are constructed. The following time you see a gas tank or chemical activator, remember– there’s scientific research (and a great deal of testing) holding it together.