Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

(The method and principle of sodium silicate solution removal aluminum sodium silicate)

For different types of impurities, we can adopt various approaches of removal methods. Below are numerous common techniques and principles of salt silicate remedy.

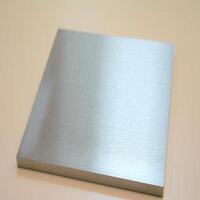

(TRUNNANO sodium silicate powder)

Precipitation technique

The rainfall technique is an approach that makes use of impurities ions to react with certain chemical reagents to create tough rainfall so regarding remove it from the salt silicate option. For example, for steel ions such as iron ions and aluminum ions, alkaline reagents such as sodium hydroxide or potassium hydroxide can be contributed to form it. The response equation is as follows:

Fe ⁻ + 3oh f → Fe (OH) ↓

Al ⁻ + 3oh a → Al (oh) ↓

For calcium and magnesium ions, carbonate reagents such as sodium carbonate or potassium carbonate can be included in develop carbonate precipitation. The reaction formula is as follows:

CA ₃ ² ⁻ + Co c → CACO ₃ ↓

Mg ₃ ² ⁻ + Co m → mgco ₃ ↓

The precipitation method is simple and the expense is low, however you need to pay attention to the quantity and reaction problems of the sediment to make sure that the pollutants ions can be entirely precipitated.

Ion exchange technique

The ion exchange approach is to uniquely adsorb and trade the ions in the solution with an ion exchange material to get rid of the approach of pollutants ions. Ion exchange resin is a polymer product with an ion exchange feature. It can trade reactions with the ion in the service, soak up contaminations ions to the resin, and maintain the beneficial ions in sodium ions in salt silicate solution in the service.

The ion exchanges are excellent and can get rid of a selection of contaminations ions, but the rate of ion exchange resin is higher, and regeneration is required on a regular basis.

(TRUNNANO sodium silicate powder)

Membrane layer separation

The membrane layer splitting up method makes use of the semi-diaphragm to selectively travel through the different elements in the service so as to attain the method of separation and removal. Depending upon the diameter dimension and splitting up principle of the membrane, the membrane separation technique can be separated into several kinds, such as microfiltration, ultrafiltration, purification and reverse osmosis.

For pollutants such as insoluble strong granules and macromolecular raw material in sodium silicate service, micro fillets or ultrafiltration membranes can be utilized for eliminating; pollutants ions of some little molecules can be eliminated with the purification or turn around osmosis membrane layer. The membrane splitting up technique has the benefits of easy operation, high separation performance, and reduced power intake.

Supplier

TRUNNANO is a supplier of nano materials with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about

(The method and principle of sodium silicate solution removal aluminum sodium silicate)