Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

**Title: “Silent Tracks: How Copper-Steel Composites Are Quietly Fixing Rail Travel’s Biggest Annoyances”**

(The Shock-Absorbing And Noise-Reducing Effects Of Copper-Steel Composite Plates In Rail Transit Are Significant)

Imagine riding a train every day. The clatter of wheels on tracks, the rattle of metal, the hum of machinery—it’s part of the experience. But what if trains could glide smoothly, with less noise and fewer bumps? Enter copper-steel composite plates. These unassuming layers of metal are making rail travel quieter, smoother, and just better. Let’s talk about why they matter.

Rail systems face two big problems: noise and vibrations. Trains are heavy, fast, and loud. The constant pounding of wheels on tracks wears down infrastructure. It also annoys passengers and people living near rails. Traditional steel plates help, but they’re not perfect. They’re tough, sure, but they don’t handle vibrations well. Noise still escapes, and tracks degrade faster. This is where copper-steel composites step in.

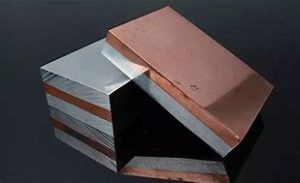

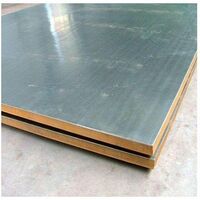

So what’s special about these plates? They’re a sandwich. A layer of copper sits between two layers of steel. Copper is softer and more flexible. Steel is strong and rigid. Together, they balance each other out. When a train rolls over the tracks, the copper layer acts like a cushion. It absorbs shocks from the wheels. The steel layers keep everything stable. This combo reduces the energy transferred to the rails. Less energy means fewer vibrations. Fewer vibrations mean less noise.

But how does it actually work? Think of vibrations as energy waves. When these waves hit the copper layer, they slow down. The copper converts some of that energy into heat. It’s like stepping on a sponge instead of a wooden board. The sponge soaks up the impact. The result? The tracks don’t shake as much. Nearby buildings and passengers feel fewer jolts.

Noise reduction is another big win. Steel alone reflects sound. It bounces noise back into the environment. Copper, though, dampens sound waves. The composite plates break up noise before it spreads. Tests show these plates cut track noise by up to 30%. For busy urban rails, that’s huge. Less screeching means happier commuters and quieter neighborhoods.

Cities are already noticing. In places like Tokyo and Berlin, copper-steel plates are being tested on high-traffic routes. Early reports say trains run smoother. Maintenance crews are spending less time fixing cracks in tracks. Passengers mention the rides feel calmer. Even nearby residents report fewer complaints about late-night rumbles.

There’s also a cost-saving angle. Stronger tracks last longer. Less vibration means less wear and tear. Cities save money on repairs. Trains consume less energy because they’re not fighting constant friction. Over time, those savings add up.

Some might ask: why not use cheaper materials? Rubber pads or plastic composites exist. But they degrade faster under heavy loads. Copper-steel holds up. It’s durable, recyclable, and handles extreme temperatures. For railways that operate 24/7, reliability is non-negotiable.

Not all challenges are solved yet. Copper is pricier than steel. Making the composite plates requires precise engineering. But as technology improves, costs are dropping. More cities are betting on this hybrid material.

(The Shock-Absorbing And Noise-Reducing Effects Of Copper-Steel Composite Plates In Rail Transit Are Significant)

Rail travel isn’t going away. As populations grow, trains will keep moving people and goods. Innovations like copper-steel composites show how small tweaks can have big impacts. Quieter rides, tougher tracks, fewer repairs—it’s a win for everyone. Next time you’re on a train, listen closely. That smooth, quiet journey might just be thanks to a clever metal sandwich beneath your feet.