Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

** Ocean Shield: Just How Titanium-Steel Duos Are Beating Rust in Marine Battles **.

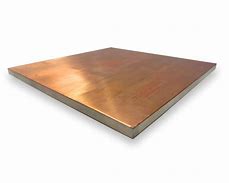

(Titanium-Steel Composite Plates Provide Long-Term Anti-Corrosion Solutions For Marine Engineering)

Saltwater is fierce. It eats through metal, damages frameworks, and prices industries billions. For years, aquatic designers have actually fought this quiet war versus corrosion. Now, a new hero has actually gotten in the scene: titanium-steel composite plates. These hybrids are transforming the game, supplying a guard that lasts longer and works harder than anything in the past.

Think of ships, oil well, or undersea pipelines. They deal with constant assaults from waves, salt, and chemicals. Conventional steel alone can not manage it. Coatings wear off. Stainless steel is costly. But titanium-steel composites? They resemble a superhero team. Steel brings brute strength. Titanium adds an almost unbreakable anti-rust layer. Together, they form an obstacle that pokes fun at deterioration.

Below’s exactly how it functions. A thin layer of titanium is bonded to a thicker steel base. The titanium acts like a bodyguard. It blocks saltwater, resists chemicals, and neglects electrochemical reactions that generally rot metal. Also if the titanium obtains scratched, it still secures the steel underneath. It’s not simply a plaster– it’s a long-lasting repair.

Real-world examinations back this up. In Japan, bridges using these plates revealed zero rust after 15 years in severe coastal conditions. Offshore wind farms in Europe switched over to titanium-steel parts and slashed maintenance costs by half. Shipbuilders report hulls long lasting twice as lengthy in between repairs. The numbers don’t lie.

Why does this matter? Money and time. Replacing corroded parts in the ocean is a headache. It means closing down procedures, hiring specialized crews, and waiting weeks for fixings. With titanium-steel compounds, structures remain intact for years. Much less downtime. Less prices. A lot more reliability.

There’s likewise an environmental win. Corrosion particles contaminates water. Frequent repairs mean even more waste and energy usage. Stronger products cut this cycle. They keep aquatic ecosystems cleaner and lower the carbon impact of consistent rebuilds.

Some bother with in advance expenses. Titanium isn’t economical. Yet right here’s the spin: over 30 years, these composites cost much less than routine steel. No constant repainting. No emergency repairs. No surprise expenditures. It resembles buying a sturdy set of boots rather than changing lightweight footwear annually.

Innovation maintains pressing better. Researchers are tweaking bonding strategies to make these plates harder. New alloys might make titanium layers also thinner without losing strength. The objective? Lighter, less costly, and much more durable options.

Marine projects are remembering. From underwater passages in Norway to floating cities in Singapore, designers are betting on titanium-steel combinations. They’re not just developing for today– they’re armor-plating the future.

(Titanium-Steel Composite Plates Provide Long-Term Anti-Corrosion Solutions For Marine Engineering)

The sea will not get kinder. Tornados will rave. Salt will certainly bite. Yet with products like these, humanity’s aquatic productions could just outlast the trends.