Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

The Penny Experiment: What Takes Place When You Zap a Coin on a Hot Plate?

(what alloy is formed when you put a penny in a hot plate)

You have actually seen cents lying around. Maybe you have actually also thrown one onto a warmer out of curiosity. Yet what really occurs when warmth fulfills that little copper coin? Allow’s go into the fiery scientific research behind this straightforward experiment.

Initially, recognize this: contemporary cents aren’t solid copper. Considering that 1982, U.S. dimes are mainly zinc with a slim copper finish. Think of them like candy-coated chocolates– other than the shell is copper, and the inside is zinc. Warm modifications things. A whole lot. When you drop a dime on a hot plate, the metals start to mingle.

Warmth speeds up atoms. As the hot plate warms the cent, the copper and zinc atoms get edgy. They shake faster and run into each various other. Gradually, this chaos creates the metals to mix. The result? A brand-new material types. This mix of steels is called an alloy.

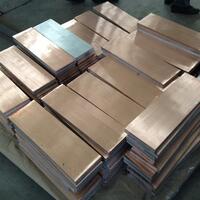

But what alloy? Zinc and copper incorporate to make brass. Brass is yellow-colored, harder than pure copper, and utilized everywhere– from musical instruments to doorknobs. To develop brass normally, you ‘d typically melt the metals with each other. However with adequate heat and time, even a hot plate can start the process.

Right here’s the catch. The cent’s copper finish is slim. The zinc core is thick. To get a real brass alloy, the metals need to totally merge. This takes more warmth than a kitchen area hot plate could supply. Many hot plates peak around 300– 400 ° F. Melting copper requires 1,985 ° F. Zinc thaws at 787 ° F. So unless your warmer is industrial-grade, the cent will not thaw. However something still happens.

At reduced warm, diffusion happens. Atoms from the zinc core seep into the copper layer. Copper atoms relocate right into the zinc. This creates a combined layer at the steel border. It’s not full brass, but it’s a begin. The cent may create a boring, patchy appearance. The glossy copper discolors as the steels connect.

Try this: hold a post-1982 dime with pliers. Warmth it uniformly on a warmer. See the surface area. After a couple of minutes, the copper finishing might bubble or peel. This reveals the zinc below. If you keep heating, the zinc oxidizes. A white powder– zinc oxide– forms. This isn’t part of the alloy. It’s an indicator the zinc is reacting with oxygen in the air.

Why care about a penny altering? Alloys shape our globe. Brass stands up to deterioration. It’s easy to shape. Without alloys, we would certainly have weak bridges, uglier precious jewelry, and squeaky instruments. The penny experiment is a little home window right into materials science. It shows how basic active ingredients transform under anxiety.

Back to the warmer. Also if you do not make excellent brass, the dime’s framework shifts. The warmth compels the metals to connect. This resembles sped-up geology. Metals “weather condition” under heat as opposed to wind or water.

Intend to evaluate it yourself? Get hold of a post-1982 dime, a warmer, and safety gear. Use tongs. Work in an aerated area. Warmth the cent. Expect shade adjustments, bubbles, or powder. Contrast it to an unheated penny. See the distinction? That’s science at work.

One last point. Pre-1982 pennies are 95% copper. Attempt heating among those. Nothing much happens. The copper could dim, yet no alloy kinds. No zinc inside. This confirms the experiment relies on the zinc-copper combo.

(what alloy is formed when you put a penny in a hot plate)

So following time you find a cent, remember– it’s not just spare adjustment. It’s a pocket-sized laboratory experiment. Warmth it up, and you’re tinkering with the exact same principles that form steels into devices, buildings, and gadgets. Okay for a little copper-coated disc.