Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

(Titanium Carbide: An Emerging Force in Modern Industry and Technology ti carbide)

Titanium Carbide: An Arising Force in Modern Market and Technology

Titanium carbide (TiC), a material with remarkable physical and chemical residential properties, is becoming a key player in contemporary market and innovation. It stands out under severe conditions such as high temperatures and pressures, and it additionally stands out for its wear resistance, solidity, electrical conductivity, and deterioration resistance. Titanium carbide is a substance of titanium and carbon, with the chemical formula TiC, featuring a cubic crystal structure comparable to that of NaCl. Its firmness competitors that of ruby, and it boasts superb thermal stability and mechanical stamina. In addition, titanium carbide shows exceptional wear resistance and electrical conductivity, dramatically improving the general performance of composite materials when made use of as a hard phase within metallic matrices. Especially, titanium carbide demonstrates outstanding resistance to a lot of acidic and alkaline services, maintaining steady physical and chemical properties also in extreme settings. Therefore, it discovers substantial applications in production devices, molds, and protective layers. For instance, in the vehicle sector, reducing devices covered with titanium carbide can substantially expand service life and lower replacement frequency, thus reducing costs. In a similar way, in aerospace, titanium carbide is used to manufacture high-performance engine elements like wind turbine blades and combustion chamber liners, boosting aircraft security and integrity.

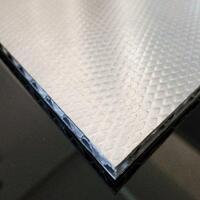

(Titanium Carbide Powder)

In recent times, with improvements in scientific research and technology, researchers have actually continually explored brand-new synthesis techniques and boosted existing procedures to boost the top quality and production volume of titanium carbide. Usual prep work approaches include solid-state reaction, self-propagating high-temperature synthesis (SHS), vapor deposition (PVD and CVD), and sol-gel processes. Each approach has its qualities and advantages; as an example, SHS can effectively minimize power intake and shorten production cycles, while vapor deposition appropriates for preparing slim films or layers of titanium carbide, making certain uniform distribution. Researchers are additionally introducing nanotechnology, such as using nano-scale raw materials or creating nano-composite materials, to more maximize the extensive efficiency of titanium carbide. These technologies not only significantly improve the toughness of titanium carbide, making it better for safety devices used in high-impact atmospheres, however additionally broaden its application as an efficient catalyst carrier, showing wide development leads. For example, nano-scale titanium carbide powder can function as an effective catalyst carrier in chemical and environmental management fields, showing comprehensive potential applications.

The application situations of titanium carbide highlight its enormous potential throughout various markets. In device and mold manufacturing, because of its exceptionally high firmness and excellent wear resistance, titanium carbide is a suitable option for making cutting tools, drills, milling cutters, and other precision handling tools. In the automotive industry, cutting devices coated with titanium carbide can significantly extend their life span and minimize replacement frequency, therefore lowering expenses. Similarly, in aerospace, titanium carbide is used to make high-performance engine components such as generator blades and burning chamber linings, improving aircraft safety and dependability. In addition, titanium carbide coatings are extremely valued for their exceptional wear and rust resistance, locating extensive usage in oil and gas removal tools like well pipeline columns and drill rods, as well as marine design structures such as ship props and subsea pipes, enhancing equipment sturdiness and security. In mining equipment and train transport sectors, titanium carbide-made wear components and coatings can greatly boost service life, lower resonance and sound, and improve functioning problems. Moreover, titanium carbide reveals substantial capacity in arising application areas. For instance, in the electronic devices market, it functions as a choice to semiconductor products because of its great electric conductivity and thermal stability; in biomedicine, it works as a finish product for orthopedic implants, promoting bone growth and lowering inflammatory reactions; in the brand-new power industry, it shows terrific potential as battery electrode products; and in photocatalytic water splitting for hydrogen production, it shows outstanding catalytic performance, giving new paths for tidy energy growth.

(Titanium Carbide Powder)

Regardless of the considerable accomplishments of titanium carbide products and relevant innovations, challenges remain in functional promo and application, such as expense concerns, large-scale production technology, ecological friendliness, and standardization. To resolve these obstacles, continual technology and boosted teamwork are critical. On one hand, strengthening essential research to check out brand-new synthesis techniques and improve existing processes can continuously lower production prices. On the various other hand, developing and perfecting industry criteria advertises worked with growth amongst upstream and downstream business, constructing a healthy and balanced ecosystem. Universities and research study institutes ought to boost instructional financial investments to grow even more top quality specialized talents, laying a solid skill foundation for the long-term development of the titanium carbide sector. In recap, titanium carbide, as a multi-functional material with terrific prospective, is slowly changing various elements of our lives. From conventional tool and mold and mildew manufacturing to emerging energy and biomedical areas, its existence is common. With the continuous growth and renovation of technology, titanium carbide is anticipated to play an irreplaceable role in much more areas, bringing better ease and benefits to human society. According to the latest marketing research records, China’s titanium carbide market reached 10s of billions of yuan in 2023, suggesting strong development energy and promising broader application prospects and development space. Scientists are likewise checking out brand-new applications of titanium carbide, such as effective water-splitting catalysts and farming changes, offering brand-new approaches for clean power advancement and attending to international food protection. As modern technology advancements and market need expands, the application areas of titanium carbide will certainly broaden better, and its significance will certainly come to be significantly noticeable. Additionally, titanium carbide locates vast applications in sports devices production, such as golf club heads coated with titanium carbide, which can significantly boost hitting precision and range; in premium watchmaking, where watch instances and bands made from titanium carbide not only boost item appearances but likewise enhance wear and rust resistance. In artistic sculpture development, artists utilize its firmness and put on resistance to develop elegant art work, enhancing them with longer-lasting vigor. To conclude, titanium carbide, with its distinct physical and chemical residential properties and wide application array, has come to be a crucial component of modern-day industry and innovation. With recurring study and technical progress, titanium carbide will certainly remain to lead a revolution in materials scientific research, supplying more possibilities to human culture.

TRUNNANO is a supplier of Molybdenum Disilicide with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about Molybdenum Disilicide, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

(Titanium Carbide: An Emerging Force in Modern Industry and Technology ti carbide)