Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

PRODUCT PARAMETERS

Description

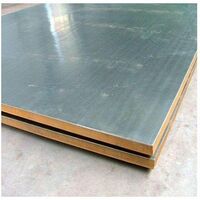

Overview of Stainless Steel Plate

A stainless steel plate is a flat sheet made from steel alloys containing chromium, offering enhanced resistance to corrosion, staining, and rust. Widely used in construction, manufacturing, and various industries for its durability, strength, and aesthetic qualities, stainless steel plates are essential materials for numerous applications.

Features of Stainless Steel Plate

Corrosion Resistance: High resistance to corrosion and rust, even in harsh environments.

Durability and Strength: Extremely durable with high tensile strength.

Temperature Resistance: Performs well under both high and low temperatures.

Hygienic Surface: Easy to clean and maintain, making it ideal for food and medical industries.

Aesthetic Appeal: Available in various finishes, enhancing architectural designs.

Recyclability: Environmentally friendly due to its recyclability and long lifespan.

(Best ing s with low and high quality titanium-plated stainless steel plate)

Specifications of Best ing s with low and high quality titanium-plated stainless steel plate

The item features titanium-plated stainless steel plates in reduced and excellent quality options. Both kinds use stainless-steel as the base material. The difference depends on material quality and titanium plating thickness. Low-quality plates use standard-grade stainless steel. Premium plates make use of premium-grade stainless steel. This boosts strength and long life. Titanium layering adds deterioration resistance. Low-grade plates have a thinner titanium layer. High-grade plates have a thicker titanium layer. This improves security against corrosion and scratches.

Longevity varies between the two. Low-quality plates deal with light use. They may bend under hefty stress. High-grade plates resist bending and contorting. They fit durable applications. Corrosion resistance is present in both. Premium plates perform better in harsh atmospheres. Deep sea or chemicals trigger minimal damages. Low-grade plates show wear quicker under comparable conditions.

Surface area finish varies. Low-grade plates have a standard polished surface area. Minor flaws like tiny bumps or uneven spots might exist. High-grade plates undergo precision sprucing up. The surface is smoother and much more uniform. Aesthetic appeal is higher.

Applications rely on high quality. Low-grade plates benefit home projects or decorative items. High-quality plates fit industrial machinery, clinical tools, or outdoor setups. Temperature level resistance is a key factor. Both kinds withstand modest warmth. High-quality plates endure extreme temperatures better. Thermal growth is very little.

Production processes influence performance. Low-grade plates make use of basic electroplating. Titanium bond is weak. Peeling off or flaking could take place over time. High-quality plates make use of sophisticated electroplating. Titanium bonds firmly to the steel base. This protects against peeling.

Price reflects high quality distinctions. Low-quality plates are affordable. Top notch plates cost much more. The higher price matches extended life expectancy and reliability. Upkeep demands are low for both. Normal cleansing with mild detergent maintains surface areas in great problem. Prevent unpleasant cleaners to avoid damaging.

Weight varies a little. Low-grade plates are lighter because of thinner products. High-grade plates are larger. The included weight sustains structural security. Personalized sizing is available for both types. Requirement density varies from 0.5 mm to 5mm. High-grade plates supply a lot more accurate density control. Tolerances are more stringent.

Ecological impact varies. Premium plates last longer. This lowers substitute regularity. Low-quality plates might require much more regular replacement. Both types are recyclable. Disposal follows typical steel reusing standards.

(Best ing s with low and high quality titanium-plated stainless steel plate)

Applications of Best ing s with low and high quality titanium-plated stainless steel plate

Titanium-plated stainless-steel plates serve numerous objectives. Their sturdiness and resistance to deterioration make them helpful in numerous markets. Low-quality titanium-plated stainless-steel plates help basic jobs. These plates often show up in attractive products. They coat surface areas like bathroom fixtures or affordable kitchen devices. The thin titanium layer adds a shiny appearance. It withstands scrapes far better than normal stainless steel. These plates set you back less. They suit jobs with tight budget plans. The lower high quality implies they use much faster in extreme problems. They may rust if the plating chips. High-grade titanium-plated stainless steel plates perform far better. They take care of heavy-duty jobs. Aerospace and medical equipment rely upon them. The thicker titanium layer supplies stronger protection. It avoids deterioration in salty or acidic environments. Chemical plants use these plates for storage tanks. Marine devices like ship components take advantage of their rust resistance. Premium cooking areas use them for long-lasting cookware. The plating remains undamaged also under high warm. Both sorts of plates operate in building and construction. Low-grade plates cover non-critical areas. High-quality plates enhance bridges or overseas structures. Electronic devices manufacturers make use of high-grade plates for conductive parts. The titanium layer enhances electrical performance. Low-grade versions in some cases appear in cheap circuitry parts. Automotive markets choose high-quality plates for engine parts. The layer minimizes rubbing and warm damage. Low-grade plates may cover exhaust pointers for look. The medical area chooses high-quality plates for medical tools. Titanium’s biocompatibility lowers infection threats. Low-grade plates are avoided below due to safety worries. Choosing between reduced and excellent quality depends upon the job. Spending plan restrictions or efficiency needs make a decision the most effective fit. Proper maintenance prolongs the life of both types. Normal cleaning prevents accumulation that weakens the coating.

Company Introduction

Welcome to Wgraj, a premier global supplier of high-quality metal cladding solutions. We specialize in providing a wide range of metal cladding products, including aluminum, steel, and copper composites, designed to meet the diverse needs of architects, builders, and designers. Our commitment to innovation, durability, and aesthetic excellence ensures that our clients receive top-tier materials for their projects. With state-of-the-art manufacturing facilities and a dedication to customer satisfaction, we deliver reliable, cost-effective solutions worldwide. Partner with us for your metal cladding needs and experience unmatched quality and service.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Best ing s with low and high quality titanium-plated stainless steel plate

What makes titanium-plated stainless steel plates better than regular ones? Titanium-plated stainless steel plates last longer. They resist rust better. They handle scratches better. High-quality versions keep their shine for years. Low-quality ones might fade faster but still perform better than regular stainless steel.

How do low-quality and high-quality titanium-plated plates differ? High-quality plates use thicker titanium layers. They polish the surface smoother. This stops corrosion and stains. Low-quality plates have thinner coatings. They might show tiny scratches sooner. Both types work for daily use, but high-quality ones stay looking new longer.

Can these plates handle high heat? Yes. Stainless steel works under high heat. Titanium plating adds extra protection. High-quality plates survive frequent high-heat use without peeling. Low-quality plates might warp or lose coating over time if overheated. Check the product’s heat limit before buying.

How do I clean titanium-plated stainless steel plates? Use mild soap and warm water. Avoid rough sponges. Dry them right after washing. High-quality plates resist water spots. Low-quality ones need more careful drying to prevent streaks. Don’t use bleach or harsh cleaners. They damage the titanium layer.

How can I spot low-quality titanium-plated plates? Check for uneven surfaces. Look for dull edges or weak shine. Low-quality plates feel lighter. They might have visible seams or rough spots. High-quality plates feel solid. Their coating looks even. Read reviews to avoid fake products.

(Best ing s with low and high quality titanium-plated stainless steel plate)

REQUEST A QUOTE

RELATED PRODUCTS

MAXI whole customizable high quality stainless steel plate with good

4x8ft 7mm 12mm thick stainless steel plate 201/hot rolled duplex 2205 stainless steel plate in Bangladesh 304

Hot high Quality sus 304 sus316 sus 410 stainless steel plate for factory supply

Aisi Jis En 201 202 301 304 31l6 430 Stainless Steel Coil Sheet Plate

Hot ing TP304 TP304L Stainless Steel Plates for elevator trim panel ISO Certified