Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

** Title: Can Nickel Alloys Take the Warm? Keeping Jet Engines Reliable **.

(Reliability Research On Nickel-Based Alloy Composite Plates In Aerospace Engine Components)

Think of the inside of a jet engine. It’s a harsh location. Temperature levels rise greater than molten lava. Pressures crush like the deepest ocean trench. Parts spin unbelievably quick, pushed to their outright limitations. Every trip, every second, demands absolute reliability. One weak spot? That’s not an option. This is where nickel alloys step into the limelight. These special metals are the unhonored heroes inside your airplane’s powerplant.

We call them superalloys permanently factor. Nickel-based alloys are difficult. They laugh in the face of extreme warm that would certainly melt ordinary steel. They resist deterioration from nasty chemicals and warm gases. They remain solid also when pressed and drawn constantly. This makes them excellent for the most popular, most stressed out components inside jet engines. Assume turbine blades, discs, and essential seals. These parts function directly in the fiery exhaust course. Their failing could be tragic. So their reliability is every little thing.

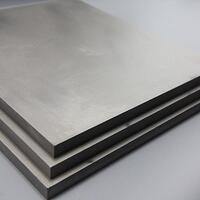

But developing an engine part isn’t just about choosing a difficult material. Engineers usually combine different products. They produce composite plates. Picture layers. Maybe a super-strong nickel alloy base. Then, unique finishings or other alloys bound on the top. Each layer includes something unique. Perhaps better warmth resistance on the surface. Or extra strength below. The objective is a material harder than any kind of solitary component.

The genuine concern is reliability. Exactly how do we understand these intricate plates won’t fracture? Exactly how do we understand they won’t break prematurely? That’s where serious study kicks in. Scientists don’t simply think. They examine, and examination hard. They expose these alloy composites to conditions also worse than an actual engine sees. They crank the warmth higher. They raise the pressure. They cycle the tension hundreds of times faster than regular flight.

Image this in the laboratory. A tiny sample of the nickel alloy composite plate beings in a special heating system. Blistering hot air blasts over it. Equipments pull and press it relentlessly. Researchers view very closely. They utilize effective microscopic lens and sensing units. They try to find the tiniest crack. They gauge just how much the material slips or deforms under anxiety. They inspect exactly how well the different layers stick together gradually. This testing mimics years of flight in just weeks or months.

The searchings for matter. This research informs us exactly just how these materials act under stress and anxiety. It shows where powerlessness could develop. It helps engineers make far better. They find out which mixes work best. They recognize for how long a part may securely last. This knowledge straight equates right into much safer, more efficient jet engines. It means aircrafts can fly further, bring extra, and burn much less gas. It implies less unanticipated fixings. Most significantly, it means guests and staff get where they’re going securely, every single time.

(Reliability Research On Nickel-Based Alloy Composite Plates In Aerospace Engine Components)

Developing these innovative products is a constant battle versus extremes. The needs of modern aerospace push the borders. Engines run hotter for much better effectiveness. They last longer in between significant overhauls. This unrelenting drive requires materials that merely won’t quit. Nickel alloys, particularly in creative composite forms, are meeting that challenge head-on. They are the peaceful structure enabling us to fly greater, quicker, and much safer. The study proceeds, pushing these extraordinary products also better.