Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

** Title: Exactly How Nickel Alloys Came To Be the Secret Heroes of Nuclear Power Plants **.

(Application Progress Of Nickel-Based Alloy Composite Plates In Key Components Of Nuclear Power Plants)

Nuclear reactor resemble gigantic problems. Every item must fit perfectly to keep things secure and reliable. One of the most important pieces in this challenge? Nickel-based alloy composite plates. These materials could sound challenging, yet their tale contains amazing scientific research and real-world influence. Allow’s simplify.

First, what also are nickel-based alloys? Think about them as super-tough materials made by mixing nickel with other metals like chromium or iron. The result? A product that laughs at extreme warmth, brushes off corrosion, and deals with stress like a champ. In nuclear plants, where temperatures skyrocket and radiation is a consistent hazard, these alloys are like the bodyguards of vital components.

Take activator stress vessels, as an example. These gigantic containers hold nuclear fuel and must make it through years of penalty. Normal steel might break under stress or warp from warmth. However include a layer of nickel-based alloy composite plates? Now you’ve obtained a material that stays strong also when points obtain wild. It’s like covering the activator in armor that never quits.

Then there’s the piping. In nuclear plants, miles of pipes lug superheated water and vapor. If these pipelines fall short, it misbehaves news. Nickel alloys action in here as well. Their rust resistance implies rust doesn’t stand a possibility. Also much better, they’re great at taking care of “thermal fatigue”– the stress that comes from warming up and cooling down repeatedly. Envision bending a paperclip back and forth until it breaks. Nickel alloys? They just keep flexing without breaking.

Cooling down systems are an additional huge deal. These systems prevent meltdowns by maintaining temperatures in check. Yet extreme chemicals and high warm can damage common products. Nickel-based composite plates act like a guard. They take the beating so the tools underneath keeps intact. It’s the distinction in between a system that lasts 5 years and one that lasts fifty.

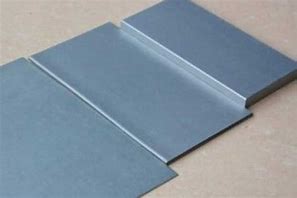

Yet it’s not just about toughness. These alloys are likewise smart. Engineers develop them layer by layer, like a state-of-the-art sandwich. The base layer might be less costly steel, while the nickel alloy rests on top, doing the hefty training. This combination conserves cash without reducing corners on safety. It resembles putting a bulletproof vest over a routine t-shirt– you get protection without the mass.

Obviously, nothing’s perfect. Making these composite plates isn’t very easy. Welding them calls for laser-like precision, and even tiny problems can trigger huge problems. Yet the benefit is huge. Plants utilizing these materials run smoother, last much longer, and face fewer shutdowns. For a market where safety and security is everything, that’s a game-changer.

What’s following? Scientists are tweaking these alloys to be even much better. Some are adding new steels to the mix, while others trying out nano-coatings. The goal? Materials that are harder, less costly, and easier to work with. As nuclear technology evolves– believe smaller sized activators or fusion power– these alloys will certainly keep playing their quiet, essential function.

(Application Progress Of Nickel-Based Alloy Composite Plates In Key Components Of Nuclear Power Plants)

So next time you find out about nuclear power, keep in mind the unhonored heroes. Nickel-based alloys might not make headings, yet without them, the lights would certainly flicker, the reactors would stutter, and the whole system would certainly wobble. They’re proof that in some cases, the stuff you never ever see matters the most.