Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

Title: “Turbo Charging the Future: Just How Copper-Steel Hybrids Are Reinventing EV Battery Power”

(Performance Optimization Of Copper-Steel Composite Plates For Conductors Of New Energy Vehicle Batteries)

Electric cars and trucks are taking over roadways all over. However what makes them zoom calmly down freeways? The response hinges on their batteries. These power packs need to be challenging, reliable, and trustworthy. One small component of this puzzle is the conductor plates inside battery systems. These plates shuttle bus electrical power where it requires to go. Now, engineers are betting on a brand-new hero: copper-steel composite plates. Allow’s go into why this combination is trembling things up.

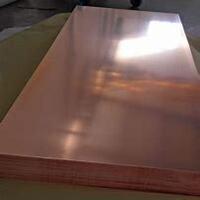

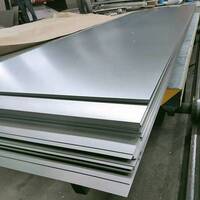

Copper is a super star for carrying out electricity. It’s been made use of in cables and circuits for life. However copper has a weak point. It’s soft. It bends. It deforms under heat. For cars and truck batteries, which deal with bumps, shakes, and wild temperature swings, that’s a problem. Steel, on the other hand, is strong. It can lose. But steel isn’t terrific at moving electrical power. So exactly how do you merge these two into something better?

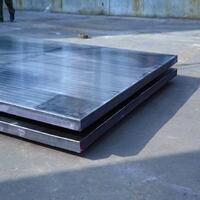

The concept is simple. Stick a layer of copper onto steel. This way, you obtain the very best of both globes. The copper deals with the electrical energy. The steel holds everything with each other. However making them function as a team isn’t simple. If the layers peel apart, the whole thing stops working. Engineers have actually spent years tweaking how these metals bond. They have actually attempted everything from warmth therapies to chemical glues. The latest developments involve lasers and nanotechnology to fuse the metals at a tiny level.

Warmth is an additional large obstacle. Batteries get hot. Steels expand when warmed. Copper and steel increase at various prices. If the composite plate can not manage this mismatch, it fractures. To repair this, scientists are testing brand-new alloy blends. These blends act like a barrier, letting copper and steel stretch without damaging apart. Some groups are even embedding small cooling networks right into home plates. These channels let coolant circulation via, maintaining temperatures steady.

Cost matters too. Copper is costly. Steel is low-cost. By blending them, firms save cash. A pure copper plate may work much better, yet it’s as well costly for mass production. The copper-steel hybrid cuts expenses without eliminating efficiency. That’s a win for carmakers trying to maintain electrical lorries cost effective.

Examining these plates is a wild adventure. Designers bolt them into prototype batteries and run brutal simulations. They blast them with warmth, freeze them, tremble them like a rough journey. The objective? See to it the plates make it through years of real-world usage. Early outcomes are appealing. Batteries with composite plates bill faster and last longer. They’re additionally lighter, which assists automobiles go further on a single fee.

The environment enjoys this technology also. Mining copper isn’t kind to the world. Using much less copper implies much less excavating. Recycling these hybrid plates is simpler also. Steel is currently one of one of the most recycled materials globally. Adding copper into the mix produces a greener lifecycle for battery components.

Cars and truck companies are competing to embrace this tech. Some claim it might slash battery prices by approximately 20%. Others hint at longer-lasting EVs hitting the marketplace by 2025. For vehicle drivers, this suggests cheaper cars and trucks, much shorter charging quits, and less bother with battery swaps.

Scientific research never ever sleeps. Groups are currently evaluating triple-layer composites, including materials like graphene or ceramics. The dream? A conductor plate that’s unbreakable, ultra-efficient, and dirt-cheap. If they pull it off, the electric change will certainly change into overdrive.

(Performance Optimization Of Copper-Steel Composite Plates For Conductors Of New Energy Vehicle Batteries)

No elegant wrap-up below. Just visualize a world where your EV’s battery is harder, smarter, and all set for anything. That world could be closer than you think.