Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

** Titanium Fulfills Steel: Can This Super-Strong Compound Revolutionize Medical Devices? **.

(Research On The Biocompatibility Of Titanium-Steel Composite Plates For Medical Equipment)

Imagine a world where the tiny screws holding your bones with each other or the plates in your back fusion surgery could last a lifetime without rusting, breaking, or annoying your body. Researchers are now checking out whether mixing titanium and steel– 2 metals known for strength– can make this dream a fact. Allow’s study why this combo may be the next large thing for medical gear.

Medical implants require to be solid, lightweight, and entirely harmless to the human body. Titanium has been the go-to product for many years since it’s biocompatible– implying it plays good with our tissues– and doesn’t activate unpleasant immune reactions. However there’s a catch. Pure titanium isn’t always strong sufficient for durable tasks like load-bearing joints or injury repair work. Steel, on the other hand, is crazy solid however has a reputation for wearing away inside the body. Also stainless-steel can launch steel ions over time, causing swelling or allergic reactions.

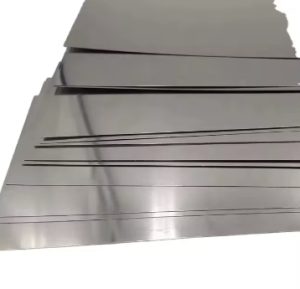

That’s where titanium-steel composite plates come in. By layering or bonding these metals, researchers aim to merge titanium’s biocompatibility with steel’s brute stamina. Consider it like a sandwich: the titanium layer encounters the body to maintain things pleasant, while the steel core handles the hefty training. But does this crossbreed really function?

Recent lab tests are promising. Researchers revealed these composite plates to substitute body fluids for months, looking for rust or toxic leaks. The titanium layer acted like a shield, safeguarding the steel from wetness and salts that normally gnaw at it. Even much better, when human cells were grown on the composite surface, they multiplied equally as well as they did on pure titanium. No inflammation, no cell fatality– simply pleased, healthy and balanced cells.

Yet toughness issues as well. Clinical plates need to endure daily deterioration. Researchers placed the titanium-steel crossbreeds through stress tests, flexing and twisting them much beyond what genuine implants would deal with. The results? The composites held up better than pure titanium and showed less lasting tiredness than steel alone. One designer compared it to “strengthened concrete for the body”– flexible yet unbreakable.

There’s another perk. Steel is less expensive than titanium. By using a composite, health centers could save money without giving up safety. A thinner layer of titanium over a steel base reduces expenses while keeping the body-friendly surface intact. This matters for large gadgets like spinal rods or crack plates, where rates can escalate.

Still, obstacles continue to be. Bonding titanium and steel isn’t simple. The steels expand at various rates when warmed, which can deteriorate the bond. Some labs are evaluating laser welding or nanostructured adhesives to resolve this. Others worry about long-lasting wear– what occurs if the titanium layer scrapes or puts on down over decades? Early animal research studies reveal no problems, however human beings live longer than guinea pig.

Medical professionals are very carefully confident. One orthopedic specialist joked, “If this functions, I’ll finally quit obtaining telephone calls at 2 a.m. concerning broken implants.” Individuals may benefit too. Faster recovery, less replacement surgeries, and say goodbye to “metal preference” some record with steel tools.

(Research On The Biocompatibility Of Titanium-Steel Composite Plates For Medical Equipment)

The race is on to best these composites. Labs in Europe, Asia, and the united state are tweaking solutions, testing new coatings, and pushing governing limits. If they prosper, the future generation of clinical implants could be tougher, safer, and less costly– confirmation occasionally, 2 metals are much better than one.