Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

**Title: Hot Bolts, Cool Tech: How Nickel Alloys Are Reinventing High-Temperature Fasteners**

(Technical Breakthroughs In The Application Of Nickel-Based Alloy Composite Plates In High-Temperature Fasteners)

Think about the hottest places machines work. Jet engines. Power plants. Chemical reactors. Things get incredibly hot inside. Keeping these machines together? That job falls to fasteners – bolts, nuts, screws. Regular metal fasteners just can’t handle that kind of heat. They soften. They stretch. They crack. This leads to leaks, failures, even dangerous shutdowns. It’s a massive headache for engineers.

Enter nickel-based alloys. These metals are tough. They laugh at extreme heat. They resist corrosion like champions. Using them for fasteners sounds perfect. There’s a big problem though. Making an entire fastener from solid nickel superalloy? That costs a fortune. It’s heavy too. It’s often overkill for the whole part. We needed a smarter solution.

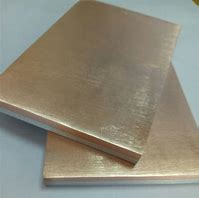

The answer came with composite plates. Imagine a sandwich. The bread is strong, affordable steel – perfect for the main body and threads of a bolt. The special filling? A thin layer of that amazing nickel alloy. This layer sits exactly where the heat and corrosion bite hardest – the head, the bearing surfaces, the areas exposed to hot gases or chemicals.

Getting this sandwich right was tricky. Sticking two very different metals together securely under extreme conditions? That’s hard. Old methods like explosion welding worked, but they were messy and limited the shapes we could make. This is where the cool breakthroughs happened.

First, new bonding techniques arrived. Think super-precise diffusion bonding or advanced roll bonding. These methods create a super-strong, seamless bond between the steel core and the nickel alloy layer. The bond stays strong even when things heat up and cool down repeatedly. Metal expands and contracts with temperature changes. Different metals do this at different rates. A weak bond would crack. These new bonds hold tight.

Second, we got better at designing the joint itself. Engineers figured out exactly how thick the nickel layer needs to be in different spots. They optimized the shape of the transition zone between the metals. This makes the fastener stronger overall. It prevents weak points.

Third, testing got serious. Simulating years of brutal heat cycles, crazy vibrations, and corrosive attacks in the lab became possible. This proved these composite fasteners wouldn’t just survive. They thrive. They last much longer than older types.

(Technical Breakthroughs In The Application Of Nickel-Based Alloy Composite Plates In High-Temperature Fasteners)

The results are real. Aircraft engines run hotter and more efficiently. Power plants need fewer emergency shutdowns for bolt replacements. Chemical plants face less risk of leaks. This nickel-steel sandwich tech means safer, more reliable machines. It saves money on maintenance and downtime. It lets engineers push performance boundaries. The next time you see a jet take off or flip on a light, remember the tiny, super-tough fasteners inside, built smarter with nickel alloy armor.