Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

** Nickel Alloy Innovations: Exactly How Aerospace Simply Obtained Stronger and Lighter **.

(Technical Breakthroughs Of Nickel-Based Alloy Composite Plates In The Aerospace Field)

Visualize a jet engine roaring to life. Inside, temperature levels struck extremes that would certainly melt common metals. Parts warp, split, or stop working. Currently picture a material challenging sufficient to laugh despite that heat, light enough to reduce fuel expenses, and reputable sufficient to manage years of supersonic anxiety. That’s the magic of nickel-based alloy composite plates– and they’re altering aerospace engineering faster than ever before.

For decades, aerospace companies looked for materials stabilizing stamina, weight, and heat resistance. Steel? Too hefty. Light weight aluminum? As well weak at high temps. Titanium? Great, but expensive. Then came nickel alloys. These steels deal with warmth like a champ, resist rust, and stay strong under stress. However also they had limitations. Early variations split under duplicated stress and anxiety or added undesirable bulk.

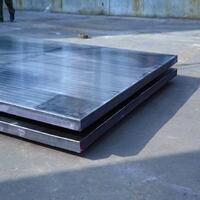

Currently, breakthroughs in composite layout are smashing those restrictions. Scientists determined how to layer nickel alloys with porcelains, carbon fibers, and even nano-materials. The outcome? Plates that are harder, lighter, and way extra versatile. Consider it like baking a cake– except each layer includes a superpower. One layer quits warmth, one more obstructs fractures, an additional shaves off weight. Together, they develop something no solitary material can attain alone.

Take engine wind turbines. Modern jets push engines harder, demanding components that survive hotter temperature levels. Nickel composite plates now line combustion chambers and wind turbine blades. They don’t just manage the warmth– they additionally reduced weight by approximately 20% contrasted to older alloys. Less weight means aircrafts shed much less gas. For airlines, that’s millions conserved annual. For the earth, it’s fewer discharges.

Brain surgery is jumping in too. Multiple-use rockets, like those from SpaceX, face ruthless conditions throughout reentry. Typical products break after a few trips. New nickel compounds? They’re built to last. By embedding heat-resistant ceramics into the alloy, engineers develop shields that shrug off the snake pit of climatic reentry. Even more launches, less substitutes.

However here’s the twist: these products aren’t simply for mega-corporations. Advancements in 3D printing allow smaller sized groups craft personalized nickel composite components. A startup can now make a wind turbine blade layer-by-layer, enhancing toughness and weight for details missions. This slashes manufacturing time and costs, opening up doors for speculative airplane and space technology.

An additional win? Safety and security. Nickel compounds resist micro-cracks– little defects that grow gradually and trigger disastrous failures. By adding carbon nanotubes or graphene, scientists enhance the steel’s framework at a microscopic level. Planes and rockets stay safer, much longer. Upkeep checks come to be less constant. Passengers fly with fewer fears.

Naturally, challenges stay. Making these composites isn’t easy. Melting and bonding different products requires exact control. A small error can deteriorate the entire plate. Companies are buying AI-driven top quality checks to spot problems unnoticeable to the human eye. Lasers check layers, algorithms forecast tension points, and robotics readjust the procedure in actual time. It’s state-of-the-art synergy.

The future? Even smarter compounds. Labs are checking alloys that “heal” little fractures by launching a securing agent when damaged. Others trying out shape-shifting products that adapt to stress patterns mid-flight. Every tweak presses aerospace closer to devices that are lighter, more secure, and virtually unbreakable.

(Technical Breakthroughs Of Nickel-Based Alloy Composite Plates In The Aerospace Field)

From guest jets to Mars rockets, nickel alloy compounds are revising the guidelines. They confirm that occasionally, the most effective remedies aren’t around finding a new product– yet remixing the old ones in ways no one saw coming. The skies’s no longer the limit. It’s simply the start.