Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

PRODUCT PARAMETERS

Description

Overview of Nickel Plate

A nickel plate refers to a thin layer of nickel deposited onto a substrate material, typically through electroplating. This process enhances the substrate’s properties such as corrosion resistance, wear resistance, and aesthetic appeal. Nickel plating is widely used in industries like automotive, electronics, and aerospace for its functional and decorative benefits.

Features of Nickel Plate

Corrosion Resistance: Provides excellent protection against rust and corrosion.

Wear Resistance: Increases durability and longevity by resisting abrasion and wear.

Enhanced Appearance: Offers a bright, reflective surface that improves aesthetics.

Electrical Conductivity: Improves electrical performance in certain applications.

Adhesion: Bonds well with various substrates including steel, brass, and aluminum.

Magnetic Properties: Depending on the type, can exhibit magnetic characteristics useful in specific applications.

(Factory Direct Inconel 600 601 625 Nickel Alloy Steel Sheet )

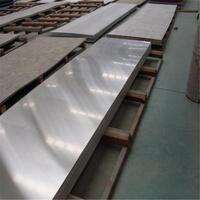

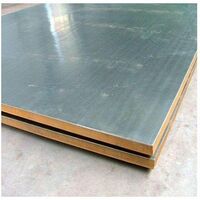

Specifications of Factory Direct Inconel 600 601 625 Nickel Alloy Steel Sheet

Manufacturing Facility Direct Inconel 600, 601, and 625 Nickel Alloy Steel Sheets offer high-performance remedies for markets requiring extreme longevity. These sheets are made for applications in rough settings. The materials stand up to corrosion, warmth, and mechanical tension properly.

Inconel 600 Nickel Alloy Steel Sheets have a high nickel-chromium composition. This makes sure strong resistance to oxidation and carburization. The sheets take care of temperature levels up to 2000 ° F( 1093 ° C)without shedding architectural honesty. Criterion density ranges from 0.5 mm to 50mm. Widths range 1000mm to 2000mm. Sizes are customizable, typically up to 6000mm. Surface area surfaces consist of hot-rolled, cold-rolled, and annealed options. The material meets ASTM B168 and ASME SB168 standards. Typical uses include heating system components and chemical processing equipment.

Inconel 601 Alloy Steel Sheets feature added light weight aluminum content. This improves oxidation resistance in high-temperature settings. The alloy does well under cyclic home heating problems. Sheets preserve toughness at temperatures up to 2200 ° F(1204 ° C). Thickness alternatives span 0.8 mm to 60mm. Requirement widths cover 1200mm to 2500mm. Personalized sizes are available. Surface area therapies consist of marinaded, blasted, or polished surfaces. Conformity with ASTM B168 and ASME SB168 makes certain reliability. Typical applications entail heat therapy fixtures and thermal processing systems.

Inconel 625 Alloy Steel Sheets incorporate niobium and molybdenum. These components enhance resistance to pitting and crevice rust. The alloy excels in salt water and acidic environments. Operating temperatures get to 1800 ° F (982 ° C). Sheets are readily available in thicknesses from 0.3 mm to 80mm. Widths array from 1000mm to 3000mm. Sizes can be tailored to project requirements. Ending up choices consist of cold-rolled, hot-rolled, or solution-annealed surfaces. Specifications include ASTM B443 and ASME SB443. The material fits aerospace elements and marine design systems.

All sheets undertake rigorous high quality checks. Dimensional precision and chemical make-up are confirmed. Mechanical testing ensures tensile stamina and hardness fulfill needs. Personalized reducing, exploration, or forming services are offered. Bulk orders ship directly from manufacturing facilities, reducing costs and lead times. Technical assistance aids with product choice and application-specific queries.

(Factory Direct Inconel 600 601 625 Nickel Alloy Steel Sheet )

Applications of Factory Direct Inconel 600 601 625 Nickel Alloy Steel Sheet

Factory Direct Inconel 600 601 625 Nickel Alloy Steel Sheets are used widely in industries needing strong resistance to heat and corrosion. These alloys handle extreme conditions. Inconel 600 works well in high-temperature settings. It is common in furnace parts, heat treatment equipment, and chemical processing systems. The alloy resists oxidation and carburization. This makes it reliable for long-term use under stress.

Inconel 601 improves on oxidation resistance. It is ideal for applications with frequent thermal cycling. Gas turbine components, industrial heating systems, and power generation units often use this alloy. The high chromium content helps form a protective oxide layer. This layer prevents degradation even at temperatures above 2000°F.

Inconel 625 stands out for its versatility. It contains molybdenum and niobium. These elements boost strength and resist pitting in corrosive environments. The alloy is popular in aerospace, marine engineering, and nuclear reactors. Aircraft exhaust systems, submarine components, and chemical plant piping rely on Inconel 625. It performs well in seawater and acidic solutions.

These nickel alloy sheets are also used in oil and gas industries. Drilling equipment, valves, and pressure vessels benefit from their durability. Harsh environments like offshore platforms demand materials that resist saltwater corrosion. Inconel alloys prevent failures in critical infrastructure.

The medical field uses these sheets for specialized devices. High-purity requirements and resistance to sterilization processes make them suitable. Surgical tools and implants made from Inconel alloys ensure safety and longevity.

Manufacturers choose factory-direct sourcing to reduce costs. Cutting out middlemen ensures quality control and faster delivery. Custom sizes and thicknesses are available for specific projects. The alloys are machinable and weldable. This allows flexibility in fabrication.

Industries prioritize materials that reduce downtime and maintenance. Inconel 600 601 625 sheets meet these demands. Their performance in extreme conditions supports efficient operations. Engineers trust these alloys for critical applications where failure is not an option.

Company Introduction

Welcome to Wgraj, a premier global supplier of high-quality metal cladding solutions. We specialize in providing a wide range of metal cladding products, including aluminum, steel, and copper composites, designed to meet the diverse needs of architects, builders, and designers. Our commitment to innovation, durability, and aesthetic excellence ensures that our clients receive top-tier materials for their projects. With state-of-the-art manufacturing facilities and a dedication to customer satisfaction, we deliver reliable, cost-effective solutions worldwide. Partner with us for your metal cladding needs and experience unmatched quality and service.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory Direct Inconel 600 601 625 Nickel Alloy Steel Sheet

What are Inconel 600, 601, 625 nickel alloy steel sheets?

These are high-performance nickel-chromium alloys. They handle extreme heat and resist corrosion. Inconel 600 resists oxidation up to 2000°F. Inconel 601 has higher aluminum content for better high-temperature strength. Inconel 625 uses niobium to prevent cracking in acidic environments. All three are used in harsh conditions.

How do Inconel 600, 601, 625 differ?

Inconel 600 has more nickel. It works in high-temperature mechanical parts. Inconel 601 adds aluminum. This improves oxidation resistance in furnaces or gas turbines. Inconel 625 includes niobium. It resists pitting in seawater and chemical solutions. Each alloy suits specific environments.

Where are these sheets commonly used?

They appear in aerospace, chemical plants, and marine equipment. Inconel 600 is for heat exchanger tubing. Inconel 601 fits furnace components. Inconel 625 serves in offshore oil rigs or nuclear reactors. All three prevent failure under stress or heat.

How to maintain Inconel alloy sheets?

Clean surfaces with mild soap and water. Avoid chlorine-based cleaners. Check for scratches or corrosion regularly. Store sheets in dry areas. Follow welding guidelines to keep corrosion resistance. Proper care extends their lifespan.

Can these sheets be customized?

Factory-direct suppliers offer cutting, rolling, or shaping. Sheets come in thicknesses from 0.5mm to 50mm. Sizes vary based on project needs. Suppliers provide material certificates. Contact sales teams for bulk orders or special requests.

(Factory Direct Inconel 600 601 625 Nickel Alloy Steel Sheet )

REQUEST A QUOTE

RELATED PRODUCTS

Custom Power 18650 Lithium Battery 5s5p Copper Nickel Busbar for battery pack Connector Copper Nickel Sheet

Custom Battery Nickel Plated Copper Strip Connector 18650 21700 32650 32700 Nickel Copper Busbar sheert

18650 26650 32650 power storage pack big electric current connector flat copper nickel busbar composite busba

18650 5s5p copper nickel busbar connector lithium battery copper nickel sheet connected to the battery copper nickel sheet

High quality 99.995% nickel sheet nickel sheet scrap nickel sheet