Discover premium surfactants for various applications. Reliable export services, competitive prices, and high performance guaranteed.

PRODUCT PARAMETERS

Description

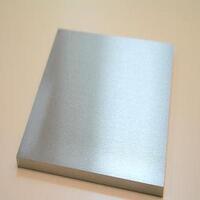

Overview of Stainless Steel Plate

A stainless steel plate is a flat sheet made from steel alloys containing chromium, offering enhanced resistance to corrosion, staining, and rust. Widely used in construction, manufacturing, and various industries for its durability, strength, and aesthetic qualities, stainless steel plates are essential materials for numerous applications.

Features of Stainless Steel Plate

Corrosion Resistance: High resistance to corrosion and rust, even in harsh environments.

Durability and Strength: Extremely durable with high tensile strength.

Temperature Resistance: Performs well under both high and low temperatures.

Hygienic Surface: Easy to clean and maintain, making it ideal for food and medical industries.

Aesthetic Appeal: Available in various finishes, enhancing architectural designs.

Recyclability: Environmentally friendly due to its recyclability and long lifespan.

(Flat Sheet Cold Rolled Hot Rolled 316 stainless steel plate 10mm for Marine steel)

Specifications of Flat Sheet Cold Rolled Hot Rolled 316 stainless steel plate 10mm for Marine steel

This 10mm thick 316 stainless steel plate is built tough for marine use. You get it cold rolled or hot rolled. Both types handle salt water very well. This material stops rust better than common 304 stainless steel. The extra molybdenum inside fights off pitting and crevice corrosion. Salt spray and harsh chemicals won’t easily damage it. This plate lasts a long time where others fail fast.

The plate measures 10 millimeters thick. Standard sizes include 1500mm x 6000mm or 2000mm x 6000mm. Other sizes are available. The width and length can be cut to fit your project. Hot rolled plates have a thicker scale layer on the surface. Cold rolled plates have a smoother, cleaner finish. Both finishes are suitable for marine building. The surface might be No.1, 2B, or BA finish. Pick the finish that fits your job.

This 316 stainless steel is very strong. It offers good tensile strength and yield strength. It performs well under stress and pressure. The material is tough enough for structural marine parts. It welds well without losing its corrosion resistance. This makes it easy to fabricate. It keeps its strength even at high temperatures. Use it for boat hulls, decks, railings, and offshore platforms. It handles propellers, shafts, and other critical components.

(Flat Sheet Cold Rolled Hot Rolled 316 stainless steel plate 10mm for Marine steel)

Applications of Flat Sheet Cold Rolled Hot Rolled 316 stainless steel plate 10mm for Marine steel

Shipbuilders use 10mm thick 316 stainless steel plates for many marine jobs. This steel is strong and fights rust very well, especially in saltwater. Hot rolled plates are common and work well for big parts. Cold rolled plates are smoother and more exact, good for jobs needing tight fits.

Builders use these plates for ship hulls and structures. The 10mm thickness gives strength without too much weight. It handles the pressure and rough conditions at sea. This steel is also good for deck hardware like railings, cleats, and ladders. It lasts longer than regular steel near saltwater.

Offshore platforms need tough materials. Builders use 10mm 316 plates for platform sections, walkways, and safety gear. The steel resists corrosion from sea spray and harsh weather. This reduces maintenance and keeps things safe.

Engine rooms are tough on materials. Heat, moisture, and chemicals cause rust. Builders use 10mm 316 plates for engine mounts, exhaust parts, and brackets. The steel handles the heat and resists chemical attack.

Coastal structures like piers, docks, and sea walls face constant saltwater. Builders use 10mm 316 plates for cladding and supports. The steel endures the wet environment for many years.

The marine industry also uses this steel for tanks holding seawater or chemicals. The 10mm thickness holds pressure. The steel does not react badly with the contents.

Piping systems on ships and offshore rigs often use 316 stainless steel. The 10mm plate can be shaped into pipes or fittings. This keeps fluids flowing without leaks or corrosion problems.

Tooling and equipment for marine work benefit from this steel. Repair shops use it for jigs, fixtures, and workbenches. It stays strong and rust-free in the shop environment.

The 10mm thickness offers a good balance. It is thick enough for strength but can still be cut, drilled, and welded. Both hot rolled and cold rolled types are available. This gives builders options depending on their exact needs and budget.

Company Introduction

Welcome to Wgraj, a premier global supplier of high-quality metal cladding solutions. We specialize in providing a wide range of metal cladding products, including aluminum, steel, and copper composites, designed to meet the diverse needs of architects, builders, and designers. Our commitment to innovation, durability, and aesthetic excellence ensures that our clients receive top-tier materials for their projects. With state-of-the-art manufacturing facilities and a dedication to customer satisfaction, we deliver reliable, cost-effective solutions worldwide. Partner with us for your metal cladding needs and experience unmatched quality and service.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Flat Sheet Cold Rolled Hot Rolled 316 stainless steel plate 10mm for Marine steel

People often ask about flat sheet 316 stainless steel plate for marine use, especially the 10mm thick kind. Here are five common questions.

What is 10mm 316 stainless steel plate? It is a strong, flat metal sheet. It is 10 millimeters thick. Type 316 stainless steel is the material. It contains molybdenum. This makes it very resistant to saltwater corrosion. It is good for boats and marine structures.

Why choose 316 stainless for marine environments? Saltwater causes rust. Type 316 fights this rust very well. Molybdenum helps stop rust spots forming. This material lasts longer near the sea than other steels. It handles harsh ocean conditions better.

What’s the difference between cold rolled and hot rolled 316 plate? Hot rolled plate goes through high heat. It cools down slowly. This makes it cheaper. Its surface finish is rougher. Cold rolled plate goes through rollers at room temperature. It gets pressed thinner and harder. Its surface is smoother and more precise. Both types are 316 stainless steel.

How do I choose between hot rolled and cold rolled? Think about your project needs. Hot rolled is usually less expensive. It works well for structural parts where the surface isn’t critical. Cold rolled costs more. It has tighter thickness control and a better finish. Use cold rolled for visible parts or where exact dimensions matter.

How do I care for and maintain 316 stainless plate? Clean it regularly with fresh water. This removes salt deposits. Use mild soap if needed. Avoid harsh cleaners like bleach. They can damage the steel. Inspect the plate periodically. Look for any dirt buildup or damage. Proper care keeps it looking good and working well for a long time at sea.

(Flat Sheet Cold Rolled Hot Rolled 316 stainless steel plate 10mm for Marine steel)

REQUEST A QUOTE

RELATED PRODUCTS

Whole Hot 304 stainless steel plate 2mm 316L stainless steel plate With Whole best er

High Quality Customized aisi 201 304 316 304l 316l Stainless Steel plate per kg

High Quality SUS201 304 30408 304L 316L 309 310S Hot Rolled ASTM Stainless Steel Sheets 0.6 mm Thickness Stainless Steel Plates

High quality stainless steel plate 0.4mm 0.5mm thick stainless steel sheet

High Standard ss 304 hot rolled sheet 3.5mm thick No.4 surface stainless steel plate wholer